The C-Mount:

A lot of thought and discussion went into the development of the C-Mount, because it needs to and does fulfill a range of requirements listed below.

- Most importantly it has to be easy and intuitive for nurses to use, i.e., do the Hot Swap, remove from the cart, drop into the charger and put a new charged battery on the cart

- It has to be open and thus easy to clean and cannot have dust or infection corners.

- It needs to be secure against up-down, back forward and sideways movements, and include spring loaded contacts to handle vibrations or jolts

- It has to be universal, in terms of positioning, vertical or horizontal, left or right, but also attach to Carts, poles etc. Direct output versions are needed for the low voltage kits like PADs, where the PAD battery acts as the Hot Swap back up.

- It has to be cost effective and easy to repair, since in some ways it is the only moving part in the system, so logically the most vulnerable part. The design combines metal for strength but also ABS parts where the system touches the battery or the the user. These are designed for easy on-location replacement.

- It has to maximize safety by automatically deactivating disconnected batteries, and reactivating on connection, thereby nullifying the danger of an accidental Li-Ion battery short circuit.∗

- It has to handle potential high currents and indeed the contacts can manage 30A.

- It needs to be bi-directional - providing power and interactive communication, but also receiving power for On-Cart Charging

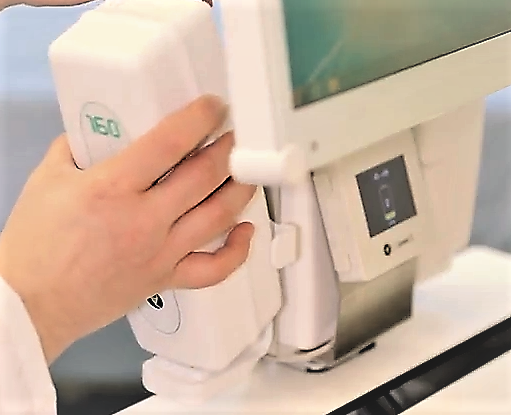

The standard Heavy duty version has a rigid metal base and 2 levels of side protection and is designed to screw on to a cart via screw holes in the back plate. The connector at the bottom is pre-wired and indeed as with all plastic parts easy to replace. The 4 wires ( without connectors) can be then run through the cart to the Hot Swap module where they are attached to a connection block. The wires are plus / minus, communication and charging. The mount has side holders to prevent horizontal movement and the top is designed to prevent vertical movement. It has a flexible lip that can be pushed up with a finger to release the battery top from its indented holding block. The Circadian battery is mounted bottom first and then pushed back into the holder.

A drop in version without Top lip is used for 2 and 4 position chargers or other applications where movement is not a consideration. In this version Gravity holds the battery in position and the spring mounted contacts cover any vibration potential.

∗ The activation/deactivation is managed by a magnetic connector in the C-Mount and in the battery. With magnetic switching the Circadian battery is protected from Short Circuit. When the battery to C-Mount magnetic connection is made there is a short delay in order to avoid any sparking. For special circumstances the Circadian batteries have an option to be removed from the C-Mount contact in a deactivated state, by holding the Logo button for longer than 5 seconds. The battery is then reactivated by placing on a charger or using a power supply to charge.